PC\104 based On-board Control System for Diesel Locomotives |

|

PC\104 based On-board Control System for Diesel Locomotives

The works for development, manufacturing and debugging of the Central Control Unit were started at the end of 2013. This unique development work was applied with the new generation diesel locomotives made by the Bryansk Machine-Building Plant.

The onboard microprocessor system is installed in the innovative shunting locomotive TEM28, which in 2017 was among the prizewinners of the contest for the best engineering development - the Association of Railway Equipment Manufacturers.

It was also applied with the promising newly-designed product – three-segment mainline diesel freight locomotive 3NE25K2M which is currently tested in the area of the Baikal-Amur Mainline.

The Central Control Unit is a software and hardware designed for ensuring functioning of control and diagnostics system of diesel locomotives of various series.

The development is distinguished by the increase as compared to the previously used systems for control of the number of I/O signals, internal diagnostics and threefold decrease in dimensions.

The information is processed in the Fastwel CPC307 single-board computer. It is designed for applications that require the use of х86 architecture of CPUs and I/O subsystem on the basis of CAN and COM-ports. СРС307 corresponds to the PC/104-Plus specification and is compatible with a large number of peripheral modules and power supply modules made in accordance with this standard and supplied by various manufacturers.

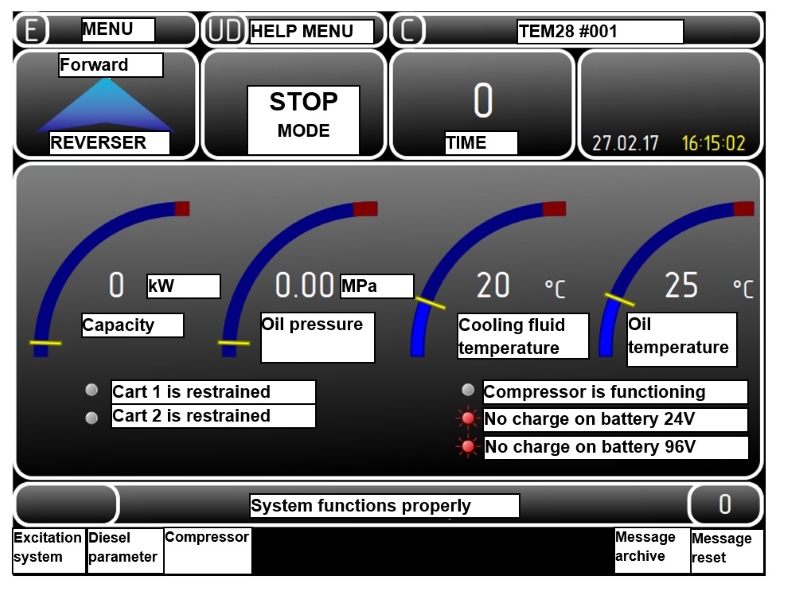

The experts of the Bryansk Machine-Building Plant successfully solved the complex task of creating a user-friendly information interface displayed at Fastwel BS04 HMI Panel.

All the signals are divided depending to their belonging to diesel locomotive systems and are presented on the corresponding virtual panels, access to which is carried out by switching the keypad of the locomotive driver's display.

The "onboard computer" monitors the state of the locomotive, connects all peripheral systems and controls the diesel engine, diesel locomotive transmission and auxiliary equipment. The microprocessor system processes information flow from the diesel locomotive through 119 digital, 17 analog and 6 temperature channels, controls 2 excitation rectifiers and 46 contact-relay units, which ensures coordinated control of all the main and auxiliary systems of the locomotive.

The information is presented on the operator's display - the transport panel PC – Fastwel BS04, which allows you to see the parameters of various nodes and subsystems of the diesel locomotive in the relevant diagnostic virtual panels (in the form of mnemonics diagram, tables, pointer indicators) in real time.

Diagnostic displays provide the ability of constant automatic monitoring the power circuit parameters, the state of the contact-relay equipment, the insulation resistance of the on-board network, the battery charge, the frequency converter of the refrigerator’s fan-engine, the converter of the compressor motor.

Therefore, the locomotive driver becomes the operator of a complex transport system. Electronics monitors the driver’s actions, gives him recommendations in the form of text messages and prevents from operating the locomotive in prohibited modes and under emergencies conditions.

Tests of this promising development work have shown that it has significant technical potential and high reliability. The enterprise received a certificate confirming that the Central Control Unit made by the Bryansk Machine-Building Plant complies with the requirements of the technical regulations of the Customs Union, which gives the right to sell the product in the market of the countries of the Eurasian Economic Union.